High Quality FRP Hand lay-up mould

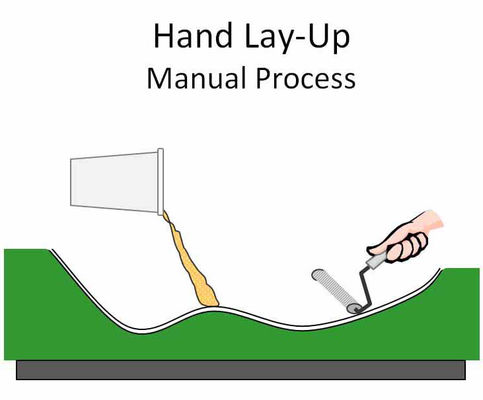

The simplest molding process, hand lay-up is used in low-volume production of large products, e.g., wind turbine components, concrete forms and radomes. A pigmented gel coat is sprayed onto the mold for a high-quality surface. When the gel coat has cured, glass reinforcing mat and/or woven roving is placed in the mold, and the catalyzed resin is poured, brushed or sprayed on. Manual rolling then removes entrapped air, compacts the composite, and thoroughly wets the reinforcement with the resin. Additional layers of mat or woven roving and resin are added for thickness. A catalyst or accelerator initiates curing in the resin system, which hardens the composite without external heat.

Q1: Which country do you export? What about the products application?

A1: Europe, North America, Australia, New Zealand, Middle East.

Q2: What about your SMC&BMC raw materials supplier?

A2: Our SMC&BMC RTM Hand lay up raw materials from domestic, we also can purchase the raw materials from the world's leading partners, IDI, Menzolit, to meet the customers' demand for various high performance composite materials.

Q3: Which process is suitable for my products?

A3: Please just send 3D drawing to us,our engineer will design the mould for you,based on your annual quantity, product structure,etc.

Q4: What's the payment terms?

A4: Payment term: 4:3:3, 40% prepayment, 30% after T1, 30% before mold shipment.

Advantages

1). We have 200ton to 2000ton hydraulic compression machines, the maximum product manufacturing ability is 8 square meters.

2). More than 12 years experience in SMC & BMC composite material products.

3). Our engineer have with rich experience in mould design. We have our own mould workshop, SMC production workshop and BMC injection molding workshop. Provide one-stop solution from SMC&BMC mould to SMC&BMC moulding products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!