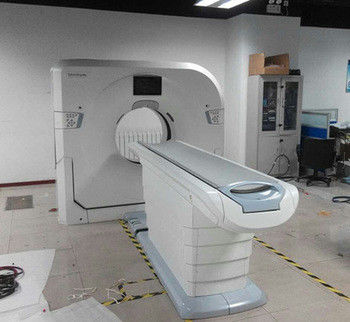

Customized fiberglass medical shell/CT machine shell/FRP medical parts

Description:

Place of Origin:Qingdao Shandong, China (Mainland)

Brand Name: Lanmon

Model Number:Customized

Application:Various Fields

Surface Treatment: Gel coat Or Paint

Technique:Hand Lay-up RTM SMC

Material:Fibreglass Reinforced Plastic

Certificate:ISO9001

Process: Hand-lay up

In the hand lay-up process, the laminate structure, commonly a single continuous strand glass mat, a woven glass mat or an advanced composite mat is manually “hand-laid” in the mold. The catalyzed thermoset resin is introduced, and the materials are formed to fit the mold surface using a “roll-out” process, as well as a number of specialized laminating tools. Additional layers of reinforced mat can be added to key structural points to enhance rigidity and performance. The Hand lay-up process is most effective when molding complex surfaces, and is commonly used in the transportation, recreation, medical, and agricultural markets.

Process: RTM

Light RTM, a closed mold process, utilizes coordinating molds comprised of a rigid “A-side” mold, the base, and a lightweight rigid “B-side” mold that fits inside or on top of the A-side mold. Prior to affixing the two molds together, a pre-sized, cut and formed continuous strand glass mat, woven glass mat or Carbon fiber reinforcement is dry-loaded into the base mold. Rather than use pressure, RTM Light uses a vacuum, which pulls the catalyzed resin through the mold cavity, saturating the fiberglass reinforcement to create a part with consistent thickness, a smooth B-side surface, and controlled fiber/resin ratios. Relative to other Closed Mold Processes, Light RTM offers lower tooling costs.

Process: SMC

The SMC / BMC molding process is a method of putting a certain amount of SMC / BMC molding material into a metal counter-die and molding the product at a certain temperature and pressure. The SMC is widely used in transportation filed like interior parts of high speed rail, auto spare parts and construction fild. The SMC / BMC molding process has the following characteristics:

1 Short molding cycle, high production efficiency, suitable for mass production of products;

2 Molded products are cheap;

3 High degree of automation and mechanization can greatly reduce labor intensity;

4 The size of the molded product is accurate, the surface is smooth, the quality is stable, and the replaceability is good;

5 Most products can be formed at one time without post-processing.

Production Process:

1st:Mould treatment:

Polish: Mould must be polished before production which will guarantee the good and solidified surface

Clean: Special detergent are used to get the dust away from the mould which will make no dark markings in the

gel coat surface.

Release agent: This will be brushed on the mould to make ejection easily.

2nd Fiberglass and resin:

Gel coat: The color of products is decided by the gel coat,with thickness of about 0.3-0.5mm. UV resistant can

be added.

Surface mat: This is to avoid the air bubble on the surface, and also make fiberglass mat invisible from the finished

surface.

Fiberglass mat: Normally we use 300g/m2 (0.6mm thickness) and 450g/m2 (0.9mm thickness). According to your

requests on the thickness and strength, we will calculate how many layers of fiberglass mat should be used.

3rdSolidify: The time required for solidifying depends on thickness and weather condition.Normally 24 hours for one

piece to solidify to avoid any deformation after demoulding.

Demould: After solidified, the product will be demoulded

Cut and trim: We will mark the trim line and hole positions on the mould,then trim according to the marks to

gaurantee the mounting dimensions

4th Adhesion: Professional mould and Temperature and worker

5th Surface treatment :

6th Painting

7th Package Solution:

Our principle: Safe and economical

We choose economical packaging on condition that there will be no damage during transportation.Shipping: We are very glad to get the freight cost information for you

as we have long term cooperated forwarder company.

Value Added Services

• Materials formulated for UV-stability, stain-resistance

• Engineering and design support

• Secondary component installation

• Bonding services

• Thermal and acoustical insulation

• Painting with your different requirement

Quality and Other Certifications

• ISO-9001

• UL-certifiable

• Flame retardant

• ROHS and EU REACH approved materials

Electrical Distribution Enclosures

• Transformer Housings

• Transformer Pads

Utility Cross-arms and Components

Benefits of Composites(frp)

• Strong, durable – long life under even extreme weather exposure

• Lightweight – easy to transport and install

• Reinforcement offer superior sidewall strength

• UV protection

• Fire retardant

• Fast turn-up on production

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!