Product Description:

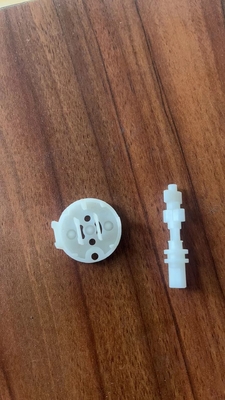

Introducing our high-quality injection mold part product, designed to meet the specific requirements of your project. This custom molded component is an essential part of the manufacturing process, ensuring precision and reliability in the production of PP molded components.

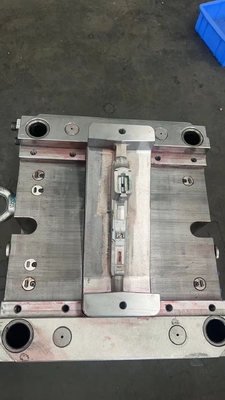

The mold gate type for this product is submarine gate, which offers a precise and controlled flow of material during the injection molding process. With a single mold cavity, this product is optimized for efficiency and consistency in producing PP molded components.

Constructed from durable steel material, this injection mold part is built to withstand the rigors of high-volume production and deliver long-lasting performance. The use of steel ensures the mold maintains its shape and integrity over time, resulting in high-quality PP molded components with every cycle.

Equipped with a water cooling system, this injection mold part is designed to regulate the temperature during the molding process effectively. The efficient cooling system helps maintain consistent part quality and dimensional accuracy, ensuring that the PP molded components meet the required specifications.

With a tolerance of 0.01mm, this injection mold part guarantees precision and accuracy in the production of PP molded components. The tight tolerance ensures that each part is consistent in size and shape, meeting the exacting standards of your project requirements.

Whether you are manufacturing automotive parts, medical devices, consumer products, or any other PP molded components, this injection mold part is the ideal solution for achieving superior quality and performance. Its reliable construction and advanced features make it a versatile and essential component for your injection molding process.

Invest in our injection mold part product today and experience the benefits of efficient production, consistent quality, and cost-effective manufacturing of PP molded components. Enhance your production capabilities and achieve greater success with this custom molded component designed to meet your specific needs.

Features:

- Product Name: injection mold part

- Mold Life: 100,000 Shots

- Runner System: Hot Runner

- Mold Cooling System: Water Cooling

- Mold Cavities: 1

- Mold Gate Type: Submarine Gate

Technical Parameters:

| Mold Gate Type |

Submarine Gate |

| Mold Cavities |

1 |

| Mold Type |

Plastic Injection Mold |

| Mold Cooling System |

Water Cooling |

| Runner System |

Hot Runner |

| Mold Core |

P20 |

| Surface Finish |

Polishing |

| Mold Life |

100,000 Shots |

| Mold Size |

Customized |

| Mold Base |

LKM |

Applications:

LANMON injection mold parts are designed for a wide range of product application occasions and scenarios, providing high-quality solutions for various industries. With the brand's commitment to excellence and innovation, these injection mold parts cater to the diverse needs of customers. Manufactured in China, these parts uphold the highest standards of quality and reliability.

The LANMON injection mold parts are crafted with a Mold Core made of P20 steel, ensuring durability and precision in every product created. With a Mold Life of up to 100,000 shots, these parts are built to last and maintain consistent performance over an extended period.

Utilizing a Mold Base from LKM, the LANMON injection mold parts boast stability and compatibility with a wide range of production processes. The Mold Gate Type, featuring a Submarine Gate, enhances the efficiency and precision of the molding process, resulting in seamless production of ABS injection parts.

Equipped with a Hot Runner Runner System, these injection mold parts are optimized for producing high-quality plastic components with minimal waste and superior quality. The Single Cavity Mold design ensures precision and accuracy in every product, meeting the exact specifications and requirements of the clients.

LANMON injection mold parts are ideal for a variety of scenarios, including mass production of plastic components, prototyping new products, and manufacturing custom-designed parts. Whether in the automotive, electronics, or consumer goods industries, these parts deliver exceptional performance and consistency.

From creating intricate ABS injection parts to molding complex plastic components, LANMON injection mold parts are the preferred choice for businesses seeking reliable and high-quality solutions. With their superior design and exceptional attributes, these parts offer unmatched value and performance in the competitive market.

Customization:

Product Customization Services for Plastic Injection Part

Brand Name: LANMON

Model Number: NONE

Place of Origin: CHINA

Mold Gate Type: Submarine Gate

Surface Finish: Polishing

Mold Cooling System: Water Cooling

Mold Core: P20

Tolerance: 0.01mm

Keywords: Multi Cavity Mold, PP Molded Component

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!