Product Description:

The FRP Wind Turbine Blades are a reliable and efficient option for renewable energy projects, offering a combination of durability, performance, and sustainability. With a weight of 500 Kilograms, these lightweight fiberglass wind blades are designed to maximize energy production while minimizing the load on the wind turbine structure.

These custom Fiberglass Wind Turbine Blades are suitable for both onshore and offshore projects, making them versatile for various wind farm installations. The 300w-50kw range ensures compatibility with a wide range of wind turbine models, providing flexibility for different power requirements.

Made from Fiber Reinforced Plastic (FRP), these wind turbine blades are known for their exceptional strength-to-weight ratio, making them an ideal choice for renewable energy applications. The material's durability and weather-resistant properties ensure reliable performance even in harsh environments, making them a long-lasting investment for wind energy projects.

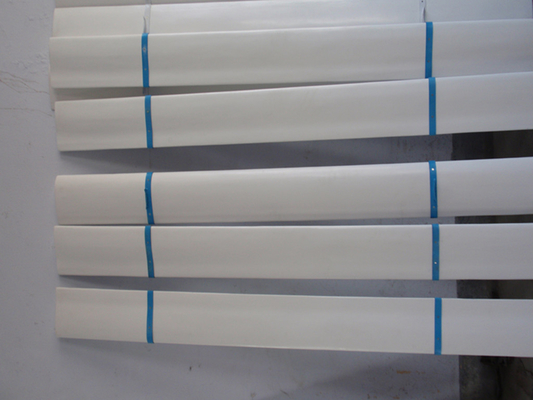

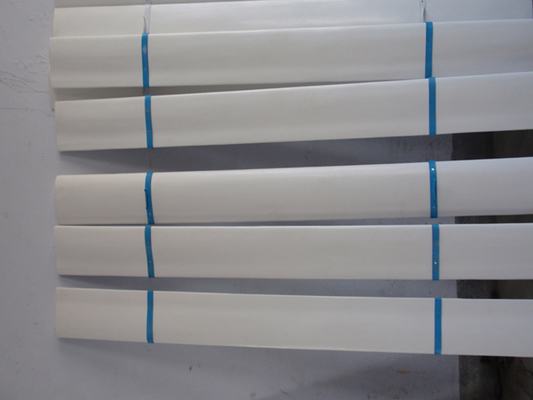

Manufactured using Hand Lay Up and RTM SMC technology, these wind turbine blades are crafted with precision and expertise to meet industry standards for quality and performance. The combination of these manufacturing techniques results in blades that are not only efficient but also durable, capable of withstanding the rigors of continuous operation in varying wind conditions.

The 40-meter rotor diameter of these FRP Wind Turbine Blades allows for optimal energy capture, maximizing the efficiency of the wind turbine system. The size and design of the blades are optimized to harness wind energy effectively, ensuring high performance and energy output.

Whether for a small-scale onshore wind project or a large-scale offshore wind farm, these Weather-Resistant Fiberglass Wind Blades are a reliable choice for renewable energy generation. Their proven performance, durability, and versatility make them a valuable component for sustainable energy production in a wide range of environments.

Features:

- Lightweight & Strong FRP Wind Turbine Blades for Stable Operation

- High-Performance Wind Rotor Blades – Fiberglass Composite Technology

- Product Name: FRP Wind Turbine Blades

- Surface Finish: Glossy

- Service: ODM OEM

- Surface: Gel Coat Paint

- Material: Fiber Reinforced Plastic

- Blade Root Connection: Bolted

Technical Parameters:

| Blade Type |

Twisted |

| Surface |

Gel Coat Paint |

| Surface Finish |

Glossy |

| Application |

CE, ISO9001 |

| Keyword |

FRP Generator Blades, FRP Wind Blades, Lightweight fiberglass wind blades, Glass fiber reinforced wind turbine blades, Composite wind blades |

| Material |

Fiber Reinforced Plastic |

| Type |

300w-50kw |

| Operating Temperature |

-40 To 60 Degrees Celsius |

| Service |

ODM, OEM |

| Number Of Blades |

3 |

Applications:

LANMON FRP wind turbine blades are a cutting-edge product designed for various application occasions and scenarios. Made of Fiber Reinforced Plastic (FRP), these composite wind blades are lightweight, durable, and efficient, making them ideal for a wide range of wind turbine systems.

Manufactured in China, these FRP wind blades from LANMON are guaranteed to meet the highest quality standards. With a weight of 500 kilograms, they are optimized for performance and reliability, making them suitable for both commercial and industrial use. The blades are designed to meet CE and ISO9001 certification requirements, ensuring they adhere to international standards for safety and quality.

The blade root connection of LANMON FRP wind turbine blades is bolted, providing a secure and stable connection to the wind turbine hub. Additionally, the surface of the blades is finished with gel coat and paint, enhancing their durability and resistance to environmental elements.

Whether you are looking to upgrade your existing wind turbine system or install a new one, LANMON FRP wind turbine blades are the perfect choice. Their lightweight fiberglass construction makes them easy to transport and install, while their high-quality manufacturing ensures long-term performance and efficiency.

Transform your wind energy production with LANMON FRP wind turbine blades, the ultimate solution for reliable and sustainable power generation. Upgrade to composite wind blades that are built to last and maximize energy output for years to come.

Customization:

Product Customization Services for LANMON FRP Wind Turbine Blades:

Brand Name: LANMON

Model Number: NONE

Place of Origin: CHINA

Rotor Diameter: 40 Meters

Blade Type: Twisted

Surface: Gel Coat Paint

Number Of Blades: 3

Service: ODM OEM

Support and Services:

Our Product Technical Support and Services for FRP Wind Turbine Blades include:

- Assistance with installation and maintenance of wind turbine blades

- Troubleshooting technical issues and providing solutions

- Conducting performance evaluations and recommending improvements

- Offering training programs for proper handling and care of the blades

- Continuous monitoring and support to ensure optimal performance

Packing and Shipping:

Product Packaging for FRP Wind Turbine Blades:

The FRP wind turbine blades are carefully packaged in a sturdy cardboard box to ensure safe transportation. Each blade is wrapped in protective foam to prevent any damage during shipping.

Shipping Information:

Our FRP wind turbine blades are shipped via a reliable courier service to ensure timely delivery. Each package is securely sealed and labeled for easy identification. Customers will receive a tracking number to monitor the shipment status.

FAQ:

Q: What is the brand name of the FRP Wind Turbine Blades?

A: The brand name of the FRP Wind Turbine Blades is LANMON.

Q: Does the FRP Wind Turbine Blades have a specific model number?

A: No, the FRP Wind Turbine Blades do not have a specific model number.

Q: Where is the FRP Wind Turbine Blades manufactured?

A: The FRP Wind Turbine Blades are manufactured in China.

Q: What material are the FRP Wind Turbine Blades made of?

A: The FRP Wind Turbine Blades are made of Fiberglass Reinforced Plastic (FRP).

Q: Are the FRP Wind Turbine Blades suitable for all wind turbine models?

A: The FRP Wind Turbine Blades are designed to be compatible with a wide range of wind turbine models. However, it's recommended to check compatibility with your specific turbine model.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!