Product Description:

The SMC and RTM Technology product represents an advanced solution in the manufacturing of fiberglass housings, specifically designed for various devices that require high-performance and durable enclosures. Utilizing Sheet Molding Compound (SMC) and Resin Transfer Molding (RTM) materials, this product offers exceptional strength and versatility, making it an ideal choice for applications demanding reliability and longevity.

One of the most notable features of this product is its high strength-to-weight ratio. The combination of SMC and RTM materials ensures that the fiberglass housing for specific device applications is both robust and lightweight. This balance is critical in environments where structural integrity must be maintained without adding excessive weight, such as in medical equipment, industrial devices, and other precision technologies. The superior mechanical properties of the SMC and RTM materials contribute to enhanced durability and resistance to impact, making the product highly reliable under various operating conditions.

The product is available in various specifications and can be customized to meet the unique requirements of different devices. This customization capability allows manufacturers to tailor the dimensions and design features precisely to the needs of their specific applications. Whether the requirement is for compact enclosures or larger housings, the flexibility of the production methods ensures that each fiberglass housing for specific device is optimized for functionality and performance.

The surface finish of the product is another distinguishing characteristic. Each fiberglass housing is coated with a gel coat paint, which not only enhances aesthetic appeal but also provides an additional layer of protection against environmental factors. This gel coat paint surface ensures that the product remains resistant to fading, chipping, and other forms of surface degradation, thereby extending the life of the housing in demanding conditions.

Corrosion resistance is a critical attribute of this product, particularly for its application as a corrosion-resistant medical shell. The inherent properties of the SMC and RTM materials, combined with the protective gel coat paint, create an enclosure that can withstand exposure to moisture, chemicals, and other corrosive agents. This makes the product exceptionally suited for medical and healthcare environments where hygiene and resistance to chemical agents are paramount. The corrosion-resistant medical shell ensures that sensitive medical devices are protected from environmental damage, thereby maintaining their operational integrity and safety.

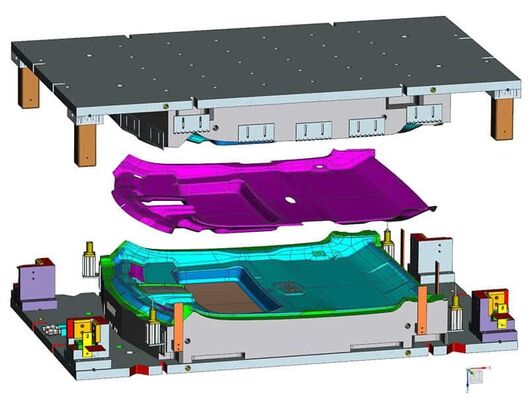

The production methods employed — compression molding and injection molding — are integral to the product’s quality and performance. Compression molding allows for the precise shaping of the SMC material under heat and pressure, resulting in strong, uniform parts with excellent surface finishes. Injection molding, used primarily for the RTM process, ensures that resin is accurately injected into molds containing fiberglass reinforcements, producing highly detailed and consistent components. These manufacturing techniques enable the production of complex and high-quality fiberglass housings that meet stringent industry standards.

In summary, the SMC and RTM Technology product offers a superior fiberglass housing for specific device needs, combining customization, high strength-to-weight ratio, and corrosion resistance into a single solution. The gel coat paint surface enhances durability and aesthetics, while the advanced production methods guarantee precision and reliability. Ideal for medical, industrial, and other specialized applications, this product stands out as a high-performance, corrosion-resistant medical shell and a versatile fiberglass housing option that meets the evolving demands of modern device manufacturing.

Features:

- High Strength-to-weight Ratio for lightweight medical-grade composite applications

- Lower Production Costs and Tooling Costs ensuring cost efficiency

- Various Specifications available, dimensions as customized for customizable medical housing

- ISO 9001 and ISO/TS 16949 Certified for quality assurance

- Smooth and Glossy Surface Finish ideal for fiberglass housing for specific device requirements

Technical Parameters:

| Material |

Sheet Molding Compound (SMC) And Resin Transfer Molding (RTM) |

| Production Method |

Compression Molding And Injection Molding |

| Quality Control |

Strict Quality Control Measures In Place |

| Size |

Customized Size |

| Customization |

Can Be Customized To Meet Specific Requirements |

| Strength |

High Strength-to-weight Ratio |

| Design Flexibility |

Can Be Molded Into Complex Shapes And Sizes |

| Weight Reduction |

Lightweight Compared To Traditional Materials |

| Service |

ODM OEM |

| Certifications |

ISO 9001 And ISO/TS 16949 Certified |

| Product Description |

EMI-Shielded Fiberglass Casing for Sensitive Medical Instruments, Modular FRP Enclosure for MRI-Compatible Rehabilitation Devices, Lightweight medical-grade composite |

Applications:

The lanmon SMC and RTM technology product is expertly designed to meet the rigorous demands of the medical industry, particularly in housing and protecting advanced rehabilitation devices. As a Modular FRP Enclosure for MRI-Compatible Rehabilitation Devices, this product offers unparalleled strength and durability while maintaining a lightweight profile. Manufactured in China using state-of-the-art compression molding and injection molding techniques, the enclosure ensures a high strength-to-weight ratio, making it ideal for medical environments where both robustness and ease of handling are critical.

One of the key application occasions for this product is in the manufacturing of rehabilitation equipment housing. The customizable size and gel coat paint surface allow for tailored solutions that meet specific requirements, ensuring compatibility with various types of rehabilitation devices. This customization capability is essential for medical device manufacturers seeking to create bespoke housings that provide optimal protection and functionality.

Moreover, the lightweight and sterilizable fiberglass case design makes it highly suitable for medical devices that require frequent sterilization and easy transport. Its resistance to harsh cleaning agents and ability to withstand repeated sterilization processes make it an excellent choice for hospital and clinical settings. The gel coat paint surface not only enhances the aesthetic appeal but also adds an extra layer of protection against environmental factors such as moisture and chemical exposure.

In practical scenarios, this product is used in MRI-compatible rehabilitation devices where electromagnetic compatibility and safety are paramount. The modular design facilitates easy assembly and maintenance, which is beneficial in fast-paced medical environments. Whether used in rehabilitation centers, hospitals, or outpatient clinics, the lanmon SMC and RTM technology product reliably supports medical professionals in delivering effective patient care.

In summary, the lanmon Modular FRP Enclosure for MRI-Compatible Rehabilitation Devices combines advanced material technology with practical design features. Its high strength-to-weight ratio, customizable sizing, and sterilizable fiberglass construction make it a superior choice for housing rehabilitation equipment and other medical devices. This product exemplifies innovation in medical device protection, ensuring safety, longevity, and performance in critical healthcare applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!