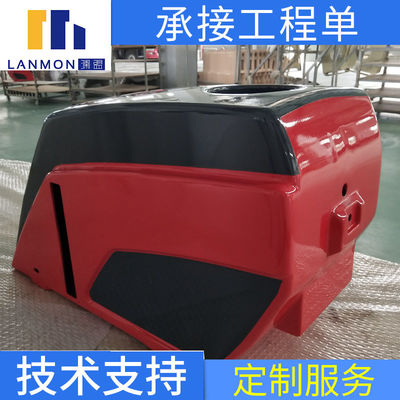

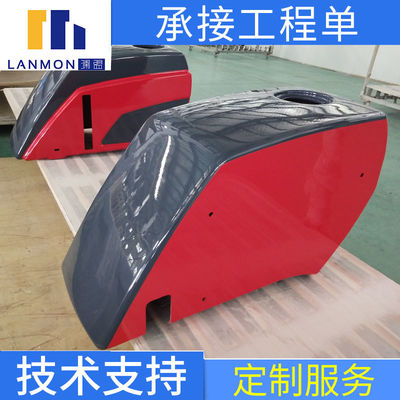

Custome fiberglass tractor hood/fiberglass agricultural enclosure/FRP tractor bonnet

Competitive Advantages of custome fiberglass tractor hood/fiberglass agricultural enclosure/FRP tractor bonnet

• Strong, durable – long life under even extreme weather exposure

• Lightweight – easy to transport and install

• Reinforcement offer superior sidewall strength

• UV protection

• Fire retardant

• Fast turn-up on production

Value Added Services

• Materials formulated for UV-stability, stain-resistance

• Engineering and design support

Quality and Other Certifications

• ISO-9001

Fiberglass is a widely used material that became popular in the past few years. One of the reasons of its relatively recent success is that it has several advantages compared to the steel: it is corrosion-free; it has significant chemical resistance and it is a lightweight material (three times less dense than steel, on average). These benefits make fiberglass suitable for automotive production, where all these advantages are very important.

Molded FRP parts for an assortment of industrial/environmental needs, such as: equipment housings, tractor parts, exterior covers, tanks, totes, and more.

Manufacturing Process of custome fiberglass tractor hood/fiberglass agricultural enclosure/FRP tractor bonnet:

1st: Mould treatment:

Polish: Mould must be polished before production which will guarantee the good and solidified surface

Clean: Special detergent are used to get the dust away from the mould which will make no dark markings in the

gel coat surface.

Release agent: This will be brushed on the mould to make ejection easily.

2nd Fiberglass and resin:

Gel coat: The color of products is decided by the gel coat,with thickness of about 0.3-0.5mm. UV resistant can

be added.

Surface mat: This is to avoid the air bubble on the surface, and also make fiberglass mat invisible from the finished

surface.

Fiberglass mat: Normally we use 300g/m2 (0.6mm thickness) and 450g/m2 (0.9mm thickness). According to your

requests on the thickness and strength, we will calculate how many layers of fiberglass mat should be used.

3rd

Solidify: The time required for solidifying depends on thickness and weather condition.Normally 24 hours for one

piece to solidify to avoid any deformation after demoulding.

Demould: After solidified, the product will be demoulded

Cut and trim: We will mark the trim line and hole positions on the mould,then trim according to the marks to

gaurantee the mounting dimensions

4th Adhesion: Professional mould and Temperature and worker

5th Surface treatment :

6th Painting

7th Package Solution:

Our principle: Safe and economical

We choose economical packaging on condition that there will be no damage during transportation.Shipping: We are very glad to get the freight cost information for you

as we have long term cooperated forwarder company.

Process: RTM PROCESS

CLOSED MOLD LAMINATING PROCESS

UTILIZING COORDINATED “A-SIDE” AND “B-SIDE” MOLDS TO CREATE PARTS WITH LESS WASTE AND BETTER “B-SIDE” COSMETICS

Light RTM, a closed mold process, utilizes coordinating molds comprised of a rigid “A-side” mold, the base, and a lightweight rigid “B-side” mold that fits inside or on top of the A-side mold. Prior to affixing the two molds together, a pre-sized, cut and formed continuous strand glass mat, woven glass mat or Carbon fiber reinforcement is dry-loaded into the base mold. Rather than use pressure, RTM Light uses a vacuum, which pulls the catalyzed resin through the mold cavity, saturating the fiberglass reinforcement to create a part with consistent thickness, a smooth B-side surface, and controlled fiber/resin ratios. Relative to other Closed Mold Processes, Light RTM offers lower tooling costs.

Utilize Light RTM when your Fiberglass Reinforced Part requires:

A strong, yet lightweight structure

Durability and weight resistance

Smooth "B-side" appearance

Benefits of LRTM vs. Open Mold laminating, include: less waste/scrap and cosmetic “B-side” surfaces. The LRTM laminating process is commonly used in the transportation, recreation, and agricultural markets.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!