Product Description:

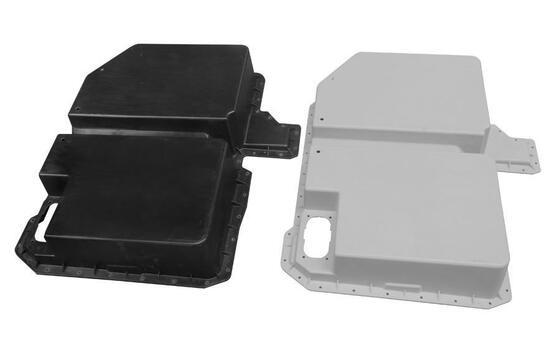

Our SMC And RTM Technology product offers a versatile solution for various industries requiring durable and cost-effective components. With a focus on customization, high strength-to-weight ratio, and certification standards, this product is ideal for applications that demand reliability and performance.

Size: Customized Size

Our SMC And RTM Technology product can be tailored to fit specific size requirements, ensuring a perfect fit for your project. Whether you need a compact fiberglass housing for a specific device or an EMI-shielded fiberglass casing for sensitive medical instruments, we can deliver the exact dimensions you need.

Strength: High Strength-to-weight Ratio

Thanks to the advanced materials and manufacturing processes used in our SMC And RTM Technology product, it offers a high strength-to-weight ratio. This means you get components that are lightweight and easy to handle, yet incredibly strong and durable. Whether you are designing rehabilitation equipment housing or structural components, our product provides the strength you can rely on.

Cost Efficiency: Lower Production Costs And Tooling Costs

Our SMC And RTM Technology product is designed with cost efficiency in mind. By utilizing innovative production techniques and materials, we are able to offer lower production costs compared to traditional manufacturing methods. Additionally, our tooling costs are optimized to provide you with a cost-effective solution for your project.

Customization: Can Be Customized To Meet Specific Requirements

One of the key features of our SMC And RTM Technology product is its high level of customization. Whether you have unique design specifications or specific requirements for your application, our product can be customized to meet your needs. From color options to surface finishes, we can tailor the product to match your exact preferences.

Certifications: ISO 9001 And ISO/TS 16949 Certified

Rest assured that our SMC And RTM Technology product meets the highest quality standards. With ISO 9001 and ISO/TS 16949 certifications, you can trust that our product has been manufactured and tested according to rigorous quality control processes. This ensures that you receive components that meet industry standards and deliver consistent performance.

Features:

- Product Name: SMC And RTM Technology

- Certifications: ISO 9001 And ISO/TS 16949 Certified

- Service: ODM OEM

- Production Method: Compression Molding And Injection Molding

- Environmental Friendliness: Recyclable And Low Emission Of Volatile Organic Compounds (VOCs)

- Strength: High Strength-to-weight Ratio

Technical Parameters:

| Cost Efficiency |

Lower Production Costs And Tooling Costs |

| Production Method |

Compression Molding And Injection Molding |

| Environmental Friendliness |

Recyclable And Low Emission Of Volatile Organic Compounds (VOCs) |

| Dimensions |

Various Specifications, As Customized |

| Surface Finish |

Smooth And Glossy |

| Surface |

Gel Coat Paint |

| Strength |

High Strength-to-weight Ratio |

| Quality Control |

Strict Quality Control Measures In Place |

| Material |

Sheet Molding Compound (SMC) And Resin Transfer Molding (RTM) |

| Certifications |

ISO 9001 And ISO/TS 16949 Certified |

Applications:

lanmon SMC And RTM Technology product is ideal for a wide range of Product Application Occasions and Scenarios due to its versatile features and attributes.

One key application scenario is the use of the product in manufacturing Corrosion-resistant medical shells. The Fiberglass Housing provided by lanmon can be customized to create protective and durable shells for various medical devices, ensuring long-lasting performance in medical settings.

Another important application of this product is in the production of EMI-Shielded Fiberglass Casings for Sensitive Medical Instruments. The EMI shielding capabilities of the product make it a perfect choice for enclosures that need to protect delicate medical instruments from electromagnetic interference.

With its certifications as ISO 9001 and ISO/TS 16949 Certified, lanmon's SMC And RTM Technology product guarantees high-quality standards and reliability in all application scenarios. The ability to customize the product to meet specific requirements further enhances its suitability for diverse applications.

Manufacturers can leverage lanmon's ODM OEM services to tailor the product according to their unique needs, whether it involves creating specialized dimensions or incorporating specific surface finishes such as Gel Coat Paint. The product's Place of Origin in CHINA signifies a commitment to efficient production and sourcing processes.

Overall, lanmon's SMC And RTM Technology product offers a comprehensive solution for creating durable, customized, and high-performance fiberglass components for a variety of Product Application Occasions and Scenarios, particularly in the medical and electronics industries.

Customization:

Product Customization Services for lanmon FRP Enclosure for Medical Equipment:

Brand Name: lanmon

Model Number: no

Place of Origin: CHINA

Certifications: ISO 9001 And ISO/TS 16949 Certified

Quality Control: Strict Quality Control Measures In Place

Surface Finish: Smooth And Glossy

Dimensions: Various Specifications, As Customized

Customization: Can Be Customized To Meet Specific Requirements

Keywords: Customizable medical housing, Corrosion-resistant medical shell

Support and Services:

Product Technical Support and Services for SMC And RTM Technology:

Our technical support team is dedicated to assisting you with any questions or issues you may encounter while using our products. We provide troubleshooting guidance, product information, and assistance with setup and configuration.

Additionally, we offer maintenance services to ensure the optimal performance and longevity of your SMC And RTM Technology products. Our service team is available to help you with product upgrades, repairs, and any other service-related needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!